Robin Wilhelm, M.Sc. Bioengineering

- PhD student

- Funktionalisierte Beschichtungen

- group: Neue Polymere und Biomaterialien

- room: 320

CN 330 - phone: +49 721 608-23052

- robin wilhelm ∂does-not-exist.kit edu

- Hermann-von-Helmholtz Platz 1

76344 Eggenstein

Reserach Interests

Engineering and optimization of fiber meshes with chemically and temporally distinct compartments for ELM fabrication

My PhD research topic revolves around engineered living materials in form of Core-Shell-Fiber structures with a focus on biocontainment. For this, I will use electrohydrodynamic 3D jetting and chemical vapor deposition to produce core-shell fibers with encapsulated bacteria. As part of my PhD, I have joined a collaborative project “ContainELMs” which is based in the DFG Priority Program SPP 2451 – Engineered Living Materials with Adaptive Functions!

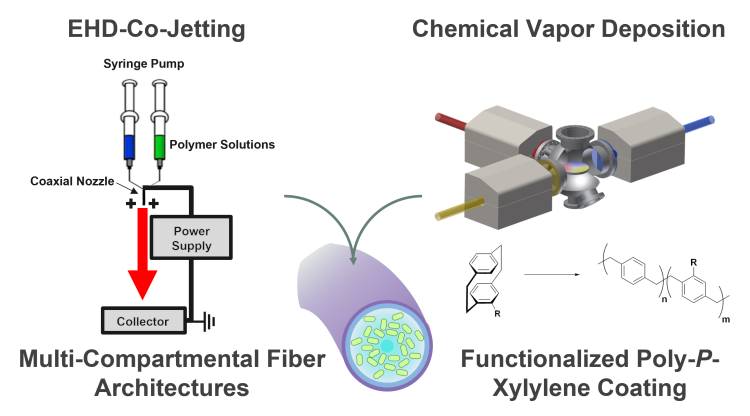

While previous studies on hybrid ELMs have demonstrated their general functionality, safe containment of living cells remains a challenge. This project addresses this gap by designing core-shell fiber structures that provide genetic and physical biocontainment. While the Bioprogrammable Materials group of the INM in Saarbrucken will genetically modify bacteria to only survive in a specific microenvironment by engineering a genetic survival-switch, the Advanced Polymers and Biomaterials group of the IFG at KIT will design host structures based on core-shell-fiber scaffolds that maintain this specific microenvironment for extended times, with a possible application for bioremediation. To achieve this goal, 3D-electrohydrodynamic (EHD) Co-jetting will be used for the spatially controlled synthesis of multicompartment fiber scaffolds containing bacteria in combination with the Chemical Vapor Deposition (CVD) process, which can provide an additional external shell with custom-tailored surface properties.

The main challenges of this project can be summarized as diffusion and survival control. To ensure the survival of the cells during the production processes, the EHD jetting and CVD parameters need to be optimized and customized for the different bacteria strains. As for the biocontainment, the escape of the bacteria from the fibers is to be prevented, while the diffusion of nutrients and reactants into the fibers must be ensured. For long-term use, the specific microenvironment needs to be maintained prospectively by controlled diffusion of biofactors out of a core reservoir into the bacteria-containing compartment. These challenges can be addressed by optimizing polymers (-blends), their respective solvents, and hydrogels.

Future applications can be diverse and include bioremediation treatments such as river water detoxification and can be spun as far as usage in industrial bioreactors where biocontainment simplifies the purification steps.

Bachelor/Master students

If you are interested in this project and want to work as a student researcher (HiWi) or want to write your bachelor/master thesis as part of this project, you can contact me anytime via email (see above).

Depending on your focus of interest, the topic of the thesis can be adapted, e.g. whether you want to focus more on doing biological work with bacteria, more on (electro‑)chemical relations between different hydrogel-organic solvent-systems for EHD-Jetting or engineer the perfect PPX-coating – lots of directions are possible. We can discuss specific topics more in detail during a personal meeting.