Bioinks for 3D Printing

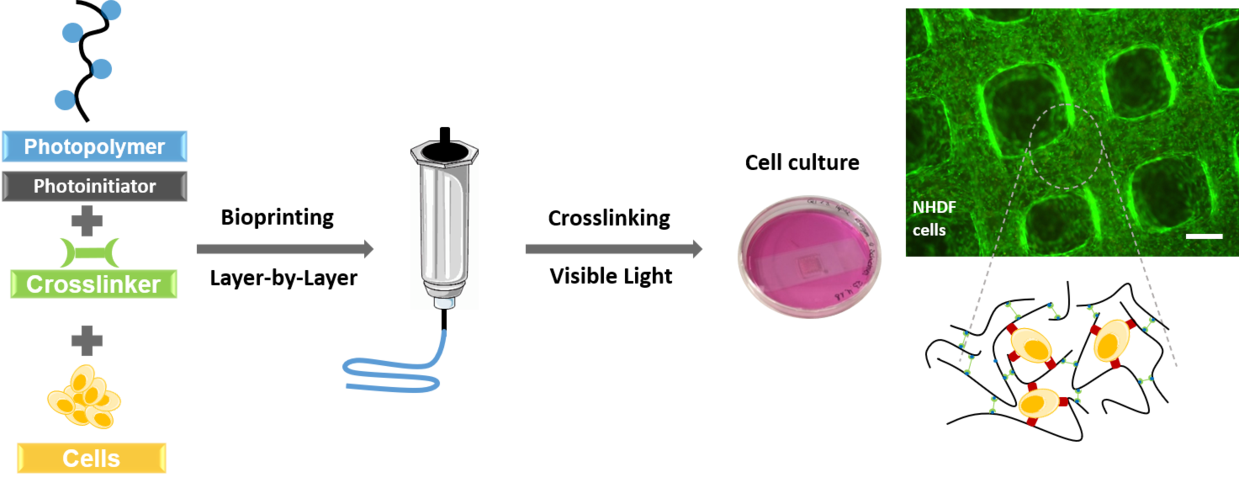

Additive manufacturing (3D printing) technologies are finding increasing utility in medical and life sciences, particularly in tissue engineering, enabling novel methods to produce three-dimensional scaffolds as promising alternatives to 2D cell culture systems. In contrast to conventional materials used in 3D printing (thermoplastics), cell-containing bioinks have to meet special mechanical and biological requirements, which include a matrix stiffness matching to the target tissue, high porosity for homogeneous cell growth and sufficiently high diffusion capacity to ensure nutrient supply. A major challenge, therefore, in biomaterial design is to find a compromise between good printing properties and biomedical demands. Light-curable gelatin-based hydrogels (water-swellable polymer networks) have proven to be promising materials for 3D Bioprinting due to the spatiotemporal control of the hydrogel formation process and their excellent biocompatibility. As photoresponsiveness of hydrogels is generally not intrinsic, biopolymers must be converted into photopolymers by incorporating photoreactive groups for chemical crosslinking to render them suitable for light-based biofabrication processes. In a typical 3D Bioprinting workflow, cells are suspended in the liquid hydrogel precursor solution which is then structured via extrusion- or inkjet-based printing technology. While 3D Bioprinting techniques address macroscopic 3D structures for tissue reconstruction, in which cells are statistically distributed, Direct Laser Writing offers the possibility to generate customized, high resolution 3D microstructures to study single cell behavior.

| Portrait | Title | Name | Contact |

|---|---|---|---|

| M.Sc. | Pohl, Eric Doctoral researcher |

+49 721 608-24014 eric pohl ∂does-not-exist.kit edu Geb. 319 / Raum 330 |

|

| Dr. | Grimm, Alisa |